Epoxy Coated Pipe

Application: Used for natural gas, petroleum, water & sewage, and pipe systems

Standard:AWWA C210

Size:60.3mm-2540mm

End:Plain End/Bevelled End, Burr Removed

Product Details

Description

The anti corrosion coating can be used for ERW/LSAW/SSAW pipe,straight seam pipe,seamless steel pipe,etc.And the coated pipes are widely used in pipeline projects in the field of petroleum,chemical, natural gas,heating,sewage treatment,water,bridges,steel structures,piling and other marine water.

|

Standard |

API 5L |

||

|

Grade |

PSL-1 |

API 5L – Gr.B/X42/X46/X52/X60/X70 etc. |

|

|

( Material) |

PSL-2 |

ISO3183 – L245/L290/L320/L360/L415/L485 etc. |

|

|

Minimum Order Quantity |

1 Ton |

||

|

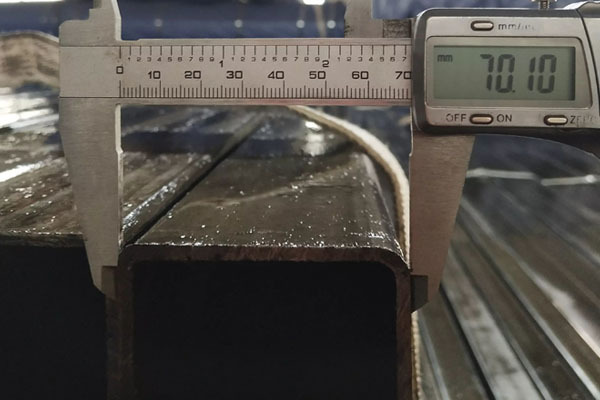

Outside Diameter Ranges |

PSL-1 |

0.405-80(in) or 10.3mm-2032mm |

|

|

PSL-2 |

4 1/2 -80(in) or 114.3mm-2032mm |

||

|

Wall Thickness Ranges |

SCH10~SCH160 Or STD,XS,XXS Or 1.73mm~59.54mm |

||

|

Length |

For 20Ft Container |

4.8m-5.8m |

|

|

(negotiable) |

For 40Ft Container |

4.8m-12m |

|

|

|

Most common choice |

6m, 12m |

|

|

Type |

Welded |

ERW,LSAW/SSAW |

|

|

Seamless |

Cold Drawn,Hot Finished,Hot Expanded |

||

|

Cap (negotiable) |

Pipe size should under DN600 |

||

|

Pipe End |

Plain end |

All sizes |

|

|

Bevel end |

Pipe size above DN50, and the thickness should greater than 3.2mm |

||

|

Our advantages |

·Diverse products(Steel pipes, pipe fittings, other fittings) |

||

|

·Any third party inspection is accepted by we company. |

|||

|

·Quick response in quotation,delivery,after-service. |

|||

|

·Focus on pipe & tube solution for project application. |

|||

|

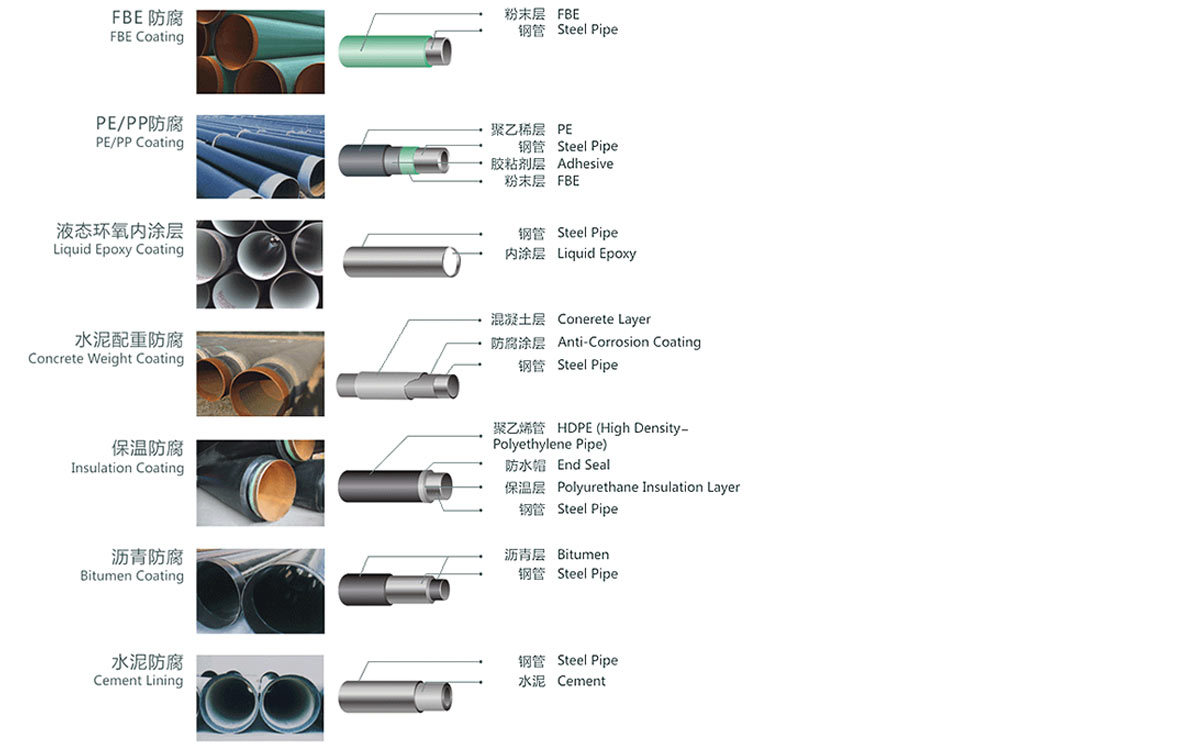

External Coating |

|

|

Coating type |

Coating Standard |

|

3LPE/3LPP |

DIN30670-1991,CAN/CSA Z245,21-2010,ISO21809-1-2009 SY/T 0413-2002,GB/T23257-2009 |

|

2LPE/2LPP |

SY/T 0315-2002,GB/T23257-2009,ISO21809-1-2009 |

|

FBE(Fusion-bond epoxy) |

SY/T 0315-2005,AWWA C213-2001,CAN/CSAZ245.20-2010,ISO218909-2-2007,API RP5L9-2001 |

|

Bitumen coating

Enamel &Tape hot-applied |

BS534-1990,AWWA203-2002,AWWA214-2000 |

|

Liquid epoxy coating |

AWWWA C210-2007 |

|

Polyurethane insulated coating |

SY/T0415-1996,CJ/T114-2000.EN253-1994 |

|

Internal Coating |

|

|

Liquid Epoxy Coating |

AWWAC210-2007 |

|

FBE |

AWWAC213-2001 |

|

Cement Mortar Lining |

BS534-1990,AWWA C205-2001 |

|

Bitumen Coating |

BS534-1990 |

Specification&Standard

Specification&Standard

|

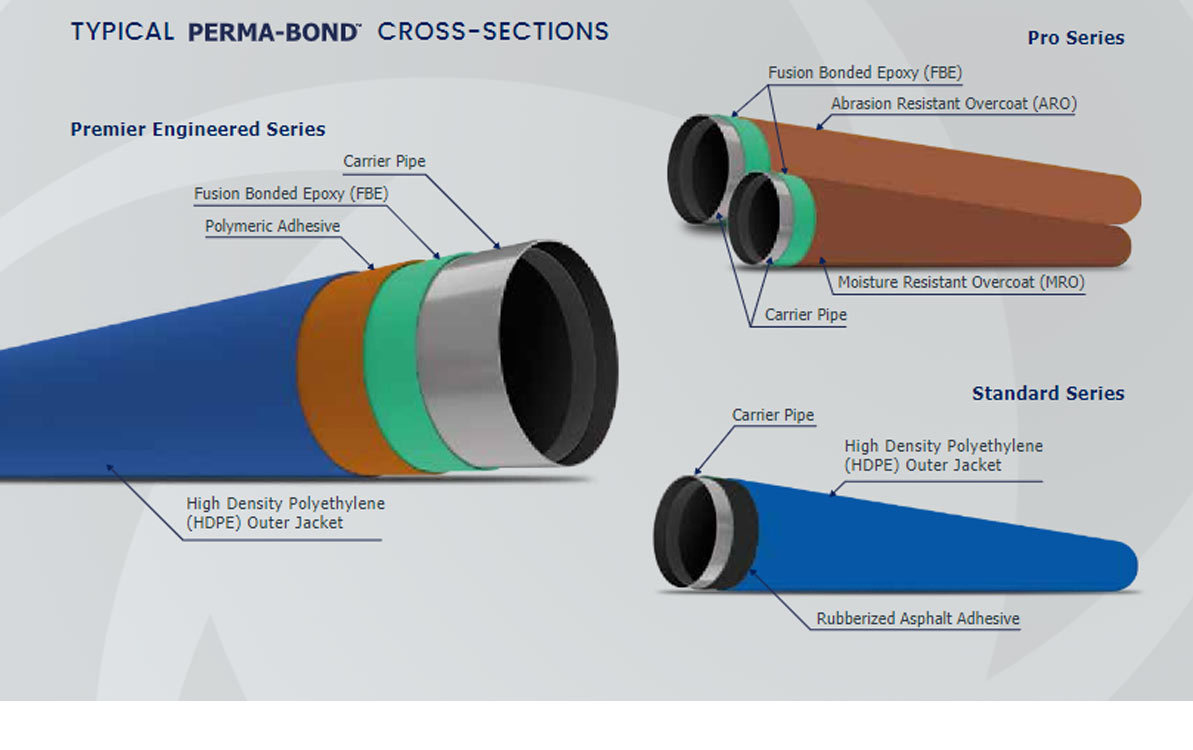

Coating Type |

Coating Layer |

Coating Thickness |

|

Three layers polyethylene |

Inside layer: epoxy (Green) |

2.0-4.5mm |

|

Mid layer: adhensive (White) |

||

|

Outsidelayer:polyethylene (Black) |

||

|

Two layers polyethylene |

Inside layer: adhensive |

2.0-4.5mm |

|

Outside layer: polythene |

||

|

Epoxy |

Epoxy |

200-400um |

|

Two layers epoxy |

Inside layer: expoxy (Green) |

400-800um |

|

Outside layer:intensity epoxy (sage green) |

||

|

Three layers polyethylene |

Inside layer: expoxy (Green) |

2.5-3mm |

AWWA C203: Coal-Tar protective coating and lining for steel water pipelines

AWWA C205: Cement mortar protective lining and coating for steel water pipe

AWWA C210: Liquid-Epoxy Coating system for interior and exterior of steel water pipeline

AWWA C213: Fusion-Bounded Epoxy coating for interior and exterior of steel water pipeline

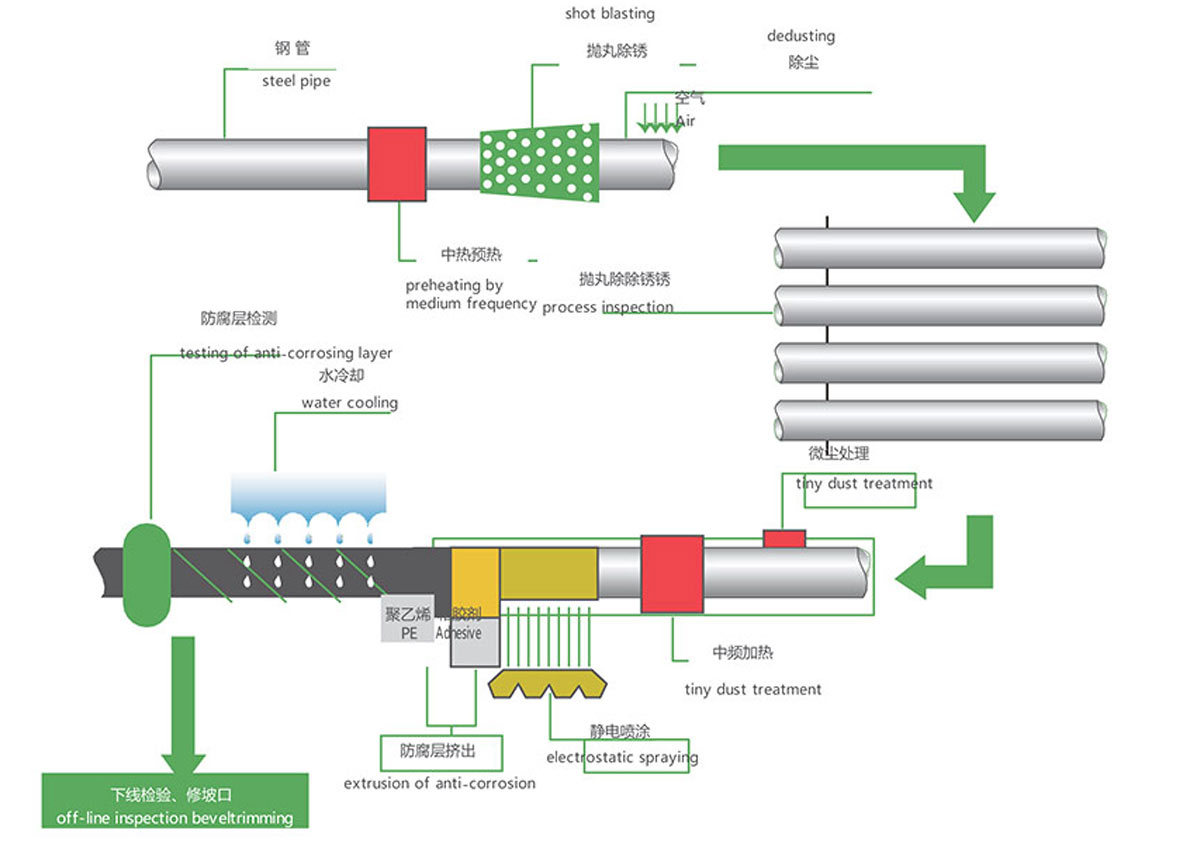

Process

Packing

Bundled package

On bundle of steel tube shall be the same in batch number, steel grade and specification.the rest of tubing less than one bundle should be tied into small bundles.

The weight of each bundle should be less than 50kg.The max weight cannot exceed 80kg of the bundle If there are special requirements.

When the length of the steel tube is greater than or equal to 6m, with at least 8 strapping bands for each bundle, divided into 3 groups and 3-2-3.

When the length of the steel tube is less than 6m, and each bundle is tied at least 5 knots and divided into 3 groups, which are 2-1-2.

When the length of the tube is greater than or equal to 3m, and each bundle is tied with at least 3 bands, divided into 3 groups, 1-1-1 showed below

Wooden box package

The wooden box is suitable for cold rolling or cold drawing seamless steel tube, polished hot rolled stainless steel tube.

When the outer diameter of steel pipe is greater than or equal 10mm, the maximum weight of the container should be 50kg.

When the outer diameter of steel pipe is less than or equal 10mm, the maximum weight of the container should be 30kg.

FACTORY APPEARANCE

Ruixing Steel Pipe was established in 2000. The company is located in Liaocheng, a well-known water city in Jiangbei, with convenient transportation. The company has tens of thousands of square meters of factory buildings, strong capital, and sufficient supply. trust.

Company products: stainless steel series, carbon steel series, aluminum series, copper series, galvanized, color coated, coiled material, seamless pipe, welded pipe, square pipe, torque pipe, round steel, angle steel, channel steel, I-beam, hexagon Steel, square steel, flat steel, steel wire, welding rod, flange cutting parts and other stainless steel and high nickel alloy steel.

CLIENT FEEDBACK

The company's products are not only well received by domestic customers, but also exported to more than 50 countries such as the European Union, the United States, Australia, Southeast Asia, and the Middle East, and have established long-term and stable cooperative relations with them. Ruixing Steel Pipe welcomes new and old customers at home and abroad to visit and negotiate for win-win cooperation!

STORAGE VIDEO

APPLICATION FIELD

The products distributed by our company are guaranteed by the manufacturer, and have a complete pre-sale, in-sale and after-sales service system. Our company has a strong standing stock of thousands of tons, sufficient supply and complete specifications. It has formed an annual inventory turnover of more than 9,000 tons and more than 800 specifications.

mechanical

boiler plant

power plant

Chemical plant

Oil Pipelines

refrigeration equipment

Water pipes

Bearing

chemical plant

Natural Gas Pipeline

QUALITY INSPECTION

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your Inquiry and we will come back to as soon as possible.

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

PACKING AND SHIPPING

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your Inquiry and we will come back to as soon as possible.

Packing and shipping

Packing and shipping

Packing and shipping

Packing and shipping

Packing and shipping

RELATED PRODUCTS

GET A FREE QUOTE