Square Stainless Steel Pipe

Size: 10×10-100×100 mm

Standard: ASTM, JIS, GB, AISI, DIN, BS,EN

Packing: Industry standard packaging or according to client's requirement

Product Details

Description

Rectangular tubes are formed from coils and then ran through a series of dies. They are are welded from the inside to form their shape. Rectangular tubes are generally used for maintenance and structural purposes.

For mechanical and structural applications, rectangular hollow sections (RHS) are popular. This is because the flat surface makes it a more economical structural solution for joining and different types of manufacturing work. For soldering or joining, RHS requires minimal edge preparation. Because of the rectangular shape of this type of hollow section, parts only need to be cut straight when joining to other flat surfaces.

Specification&Standard

|

SIZE mm |

WEIGHT kg/m |

EST. LBS. PER FT. |

|

SIZE mm |

WEIGHT kg/m |

|

|

EST. LBS. PER FT. |

||||||

|

40 x 20 x 1.60 |

1.380 |

0.93 |

|

150 x 100 x 6.30 |

22.400 |

15.08 |

|

40 x 20 x 2.60 |

2.100 |

1.41 |

|

150 x 100 x 8.00 |

27.700 |

18.64 |

|

50 x 30 x 1.60 |

1.880 |

1.27 |

|

150 x 100 x 10.00 |

35.714 |

24.04 |

|

50 x 30 x 2.60 |

2.920 |

1.97 |

|

160 x 80 x 3.20 |

11.500 |

7.74 |

|

50 x 30 x 2.90 |

3.320 |

2.23 |

|

160 x 80 x 4.00 |

14.300 |

9.62 |

|

50 x 30 x 3.20 |

3.490 |

2.35 |

|

160 x 80 x 5.00 |

17.400 |

11.71 |

|

50 x 30 x 4.00 |

4.410 |

2.97 |

|

160 x 80 x 6.30 |

21.400 |

14.40 |

|

60 x 40 x 2.60 |

3.730 |

2.51 |

|

160 x 80 x 8.00 |

26.400 |

17.77 |

|

60 x 40 x 2.90 |

4.230 |

2.85 |

|

160 x 80 x 10.00 |

32.545 |

21.87 |

|

60 x 40 x 3.20 |

4.500 |

3.03 |

|

160 x 90 x 4.50 |

16.600 |

11.17 |

|

60 x 40 x 4.00 |

5.670 |

3.82 |

|

160 x 90 x 5.60 |

20.400 |

13.73 |

|

70 x 40 x 2.90 |

4.690 |

3.16 |

|

160 x 90 x 7.10 |

25.300 |

17.03 |

|

70 x 40 x 4.00 |

6.300 |

4.24 |

|

160 x 90 x 8.80 |

30.500 |

20.53 |

|

80 x 40 x 2.60 |

4.550 |

3.06 |

|

160 x 90 x 10.00 |

34.100 |

22.95 |

|

80 x 40 x 2.90 |

5.140 |

3.46 |

|

180 x 100 x 4.00 |

16.800 |

11.31 |

|

80 x 40 x 3.20 |

5.500 |

3.70 |

|

180 x 100 x 5.00 |

20.500 |

13.80 |

|

80 x 40 x 4.00 |

6.930 |

4.66 |

|

180 x 100 x 5.60 |

23.000 |

15.48 |

|

80 x 40 x 5.00 |

8.470 |

5.70 |

|

180 x 100 x 6.30 |

25.400 |

17.09 |

|

80 x 40 x 6.30 |

10.400 |

7.00 |

|

180 x 100 x 7.10 |

28.600 |

19.25 |

|

90 x 50 x 2.60 |

5.370 |

3.61 |

|

180 x 100 x 8.80 |

34.700 |

23.35 |

|

90 x 50 x 3.20 |

6.640 |

4.47 |

|

180 x 100 x 10.00 |

38.800 |

26.11 |

|

90 x 50 x 4.00 |

8.180 |

5.51 |

|

180 x 100 x 12.50 |

46.900 |

31.56 |

|

90 x 50 x 5.00 |

10.000 |

6.73 |

|

200 x 100 x 4.00 |

18.000 |

12.11 |

|

90 x 50 x 6.30 |

12.300 |

8.28 |

|

200 x 100 x 5.00 |

22.100 |

14.20 |

|

90 x 50 x 7.10 |

13.700 |

9.22 |

|

200 x 100 x 6.30 |

27.400 |

18.44 |

|

100 x 50 x 3.60 |

7.980 |

5.37 |

|

200 x 100 x 8.00 |

34.000 |

22.88 |

|

100 x 50 x 4.50 |

9.830 |

6.62 |

|

200 x 100 x 10.00 |

40.600 |

27.32 |

|

100 x 50 x 5.60 |

12.000 |

8.08 |

|

200 x 120 x 4.00 |

19.300 |

12.99 |

|

100 x 50 x 7.10 |

14.800 |

9.96 |

|

200 x 120 x 5.00 |

23.700 |

15.95 |

|

100 x 50 x 8.00 |

16.400 |

11.04 |

|

200 x 120 x 6.30 |

29.600 |

19.92 |

|

100 x 60 x 3.20 |

7.510 |

5.05 |

|

200 x 120 x 8.00 |

36.500 |

24.56 |

|

100 x 60 x 3.60 |

8.550 |

5.75 |

|

200 x 120 x 8.80 |

36.900 |

24.83 |

|

100 x 60 x 4.50 |

10.500 |

7.07 |

|

200 x 120 x 10.00 |

45.100 |

31.62 |

|

100 x 60 x 5.60 |

12.900 |

8.68 |

|

200 x 120 x 12.50 |

54.700 |

38.87 |

|

100 x 60 x 6.30 |

13.500 |

9.09 |

|

200 x 120 x 14.20 |

60.900 |

43.64 |

|

100 x 60 x 7.10 |

15.900 |

10.70 |

|

220 x 80 x 6.00 |

26.816 |

18.02 |

|

100 x 60 x 8.80 |

19.200 |

12.92 |

|

220 x 120 x 6.30 |

31.600 |

21.27 |

|

100 x 80 x 6.3 |

16.370 |

11.02 |

|

220 x 120 x 8.00 |

39.400 |

26.52 |

|

110 x 60 x 3.60 |

9.050 |

6.09 |

|

220 x 120 x 10.00 |

46.200 |

31.09 |

|

110 x 60 x 4.50 |

11.100 |

7.47 |

|

220 x 120 x 12.50 |

58.700 |

39.51 |

|

110 x 60 x 5.60 |

13.600 |

9.15 |

|

220 x 120 x 14.20 |

65.400 |

44.01 |

|

110 x 60 x 7.10 |

16.800 |

11.31 |

|

250 x 150 x 5.00 |

29.900 |

20.12 |

|

110 x 60 x 8.80 |

20.100 |

13.53 |

|

250 x 150 x 6.30 |

37.300 |

25.10 |

|

110 x 70 x 3.20 |

8.510 |

5.73 |

|

250 x 150 x 8.00 |

46.500 |

31.29 |

|

110 x 70 x 4.00 |

10.800 |

7.27 |

|

250 x 150 x 10.00 |

56.300 |

37.89 |

|

110 x 70 x 5.00 |

12.700 |

8.55 |

|

250 x 150 x 12.50 |

68.300 |

45.97 |

|

110 x 70 x 6.30 |

15.500 |

10.43 |

|

260 x 140 x 6.30 |

37.500 |

25.23 |

|

120 x 60 x 3.20 |

8.510 |

5.73 |

|

260 x 140 x 8.00 |

46.900 |

31.56 |

|

120 x 60 x 4.00 |

10.600 |

7.13 |

|

260 x 140 x 10.00 |

57.600 |

38.76 |

|

120 x 60 x 5.00 |

13.000 |

8.75 |

|

260 x 140 x 12.50 |

70.400 |

47.38 |

|

120 x 60 x 6.30 |

16.100 |

10.84 |

|

260 x 140 x 14.20 |

78.800 |

53.03 |

|

120 x 60 x 7.10 |

17.900 |

12.05 |

|

260 x 180 x 6.30 |

41.500 |

27.93 |

|

120 x 60 x 8.80 |

21.500 |

14.47 |

|

260 x 180 x 8.00 |

52.000 |

35.00 |

|

120 x 80 x 3.20 |

12.100 |

8.14 |

|

260 x 180 x 10.00 |

63.900 |

43.00 |

|

120 x 80 x 6.30 |

17.500 |

11.78 |

|

260 x 180 x 12.50 |

78.300 |

52.70 |

|

140 x 70 x 4.00 |

12.500 |

8.41 |

|

260 x 180 x 14.20 |

87.700 |

59.02 |

|

140 x 70 x 5.00 |

15.400 |

10.36 |

|

300 x 100 x 5.00 |

30.268 |

20.34 |

|

140 x 70 x 6.30 |

19.000 |

12.79 |

|

300 x 100 x 8.00 |

47.679 |

32.04 |

|

140 x 70 x 7.10 |

21.200 |

14.27 |

|

300 x 100 x 10.00 |

58.979 |

39.63 |

|

140 x 70 x 8.80 |

25.600 |

17.23 |

|

300 x 200 x 5.00 |

37.800 |

25.44 |

|

140 x 80 x 3.20 |

10.500 |

7.07 |

|

300 x 200 x 6.30 |

47.100 |

31.70 |

|

140 x 80 x 4.00 |

13.100 |

8.82 |

|

300 x 200 x 8.00 |

59.100 |

39.77 |

|

140 x 80 x 5.00 |

16.200 |

10.90 |

|

300 x 200 x 10.00 |

72.000 |

48.46 |

|

140 x 80 x 6.30 |

20.000 |

13.46 |

|

300 x 200 x 12.00 |

88.000 |

59.22 |

|

140 x 80 x 8.00 |

24.800 |

16.69 |

|

|

|

|

|

140 x 80 x 10.00 |

30.200 |

20.32 |

|

|

|

|

|

150 x 100 x 3.20 |

12.000 |

8.08 |

|

|

|

|

|

150 x 100 x 4.00 |

14.900 |

10.03 |

|

|

|

|

Dimensional Tolerances

|

Dimensional Tolerances |

|||

|

Outside Diameter: |

Twist: |

Maximum twist per 3 feet of length |

|

|

Largest outside dimension |

Outside tolerance including convexity and concavity |

Longest outside dimension |

|

|

up to 2 1/2" |

±.020" |

2" to 2 1/2"inclusive |

.062" |

|

over 21/2" to 31/2" inclusive |

±.025" |

over 21/2" to 4" inclusive |

.075" |

|

over 31/2" to 51/2" inclusive |

±.030" |

over 4" to 6" inclusive |

.087" |

|

over 51/2" |

±1% |

over 6" to 8" inclusive |

100" |

|

Tolerances include allowance for convexity or concavity. For |

over 8" |

112" |

|

|

Straightness: |

|||

|

.125" x (total length) ÷ 5 |

|||

|

Wall Thickness: |

Squareness of Sides: |

||

|

Maximum allowable variation |

±10% |

Adjacent sides may deviate from 90° by a tolerance of plus or minus 2 degrees maximum. |

|

|

(wall thickness is to be measured at the center of the flat, exclusive |

|||

|

Worner Radii: |

Flash: |

||

|

The radius of any outside corner shal not exceed three times |

Structural tubing usually is supplied flash-in. The height of the |

||

ASTM A500 Grade B,

ASTM A513 (1020-1026)

ASTM A36 (A36)

EN 10210:S235,S355,S235JRH,

S355J2H,S355NH

EN 10219:S235,S355,S235JRH,

S275J0H, S275J2H, S355J0H, S355J2H

ASTM A500 Cold Formed Welded and Seamless Carbon Steel Steel Structural Tubing in Round and Shapes

|

|

Chemistry-Ladle Analysis |

|||

|

Carbon |

Manganese |

Phosporous |

Sulfur |

|

|

A501 (A36) |

0.26% max |

- |

0.04% max |

0.05% max |

|

A500A |

0.26% max |

- |

0.04% max |

0.05% max |

|

A500B |

0.26% max |

- |

0.04% max |

0.05% max |

|

A500C |

0.23% max |

1.35% max |

0.04% max |

0.05% max |

|

Copper, when copper steel is specified, 0.20% minimum. |

||||

|

Mechanical Properties |

||||

|

Grade Designation |

Grade |

Tensile Strength |

Yield Strength Minimum |

Elongation In 2 Inches Minimum |

|

Condition |

Minimum |

|||

|

A501 (A36) |

Hot Formed |

58,000 psi |

36,000 psi |

23% |

|

A500A |

Cold Formed |

45,000 psi |

39,000 psi |

25% |

|

A500B |

Cold Formed |

58,000 psi |

46,000 psi |

23% |

|

A500C |

Cold Formed |

62,000 psi |

50,000 psi |

21% |

Chemical composition

Steel Grade: Q195, Q215, Q235, Q345, S235JR, S275JR, SS4007

|

Data |

Elements(%) |

||||

|

Materal Grade |

C |

Mn |

S |

P |

Si |

|

Q195 |

0.06-0.12 |

0.25-0.50 |

<0.05 |

<0.045 |

<0.30 |

|

Q215 |

0.09-0.15 |

0.25-0.55 |

<0.05 |

<0.045 |

<0.30 |

|

Q235 |

0.12-0.20 |

0.30-0.70 |

<0.045 |

<0.045 |

<0.30 |

|

Q345 |

<0.20 |

1.0-1.6 |

<0.04 |

<0.04 |

<0.55 |

Mechanical property

|

Materal Grade |

Yield point (Mpa) |

Tensile Strength (Mpa) |

Elongation(%) |

|

Q195 |

>195 |

315-430 |

32-33 |

|

Q215 |

>215 |

335-450 |

26-31 |

|

Q235 |

>235 |

375-500 |

24-26 |

|

Q345 |

>345 |

470-630 |

21-22 |

Tolerance:

|

Length |

+/- 50 MM |

|

Wall Thickness |

+/- 12.5% |

|

Weight |

+/- 8% |

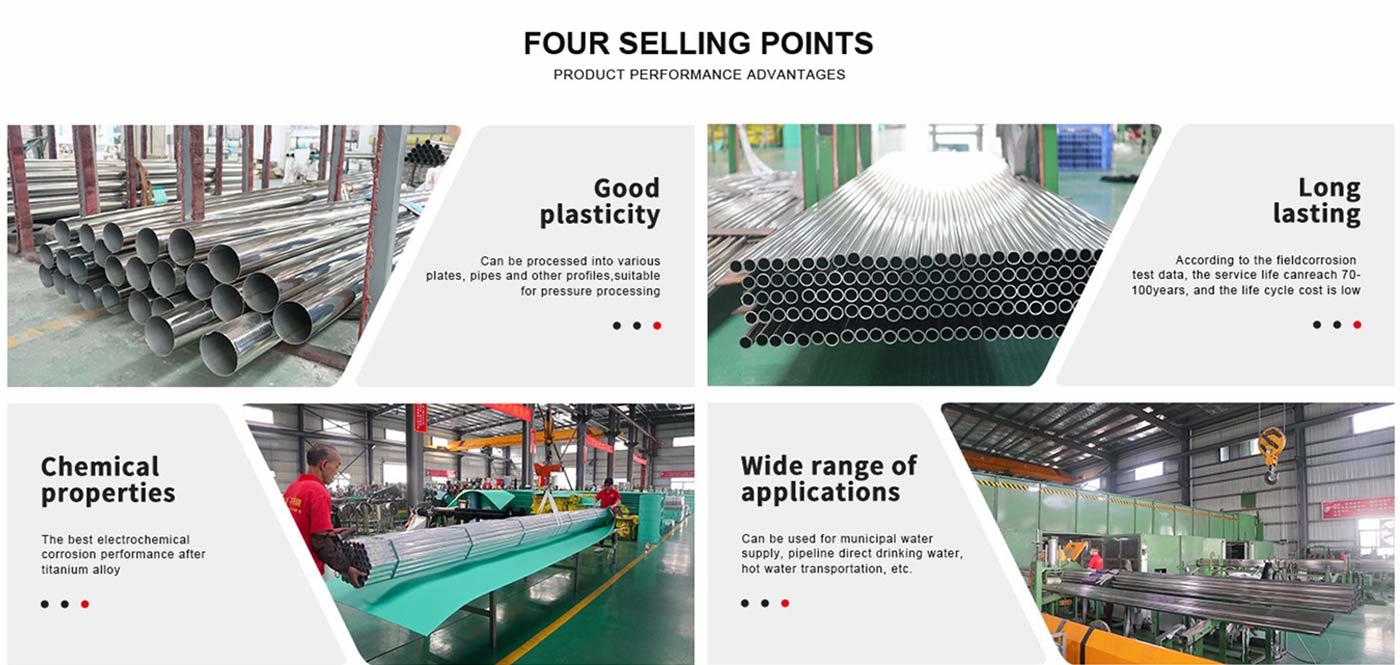

FACTORY APPEARANCE

Ruixing Steel Pipe was established in 2000. The company is located in Liaocheng, a well-known water city in Jiangbei, with convenient transportation. The company has tens of thousands of square meters of factory buildings, strong capital, and sufficient supply. trust.

Company products: stainless steel series, carbon steel series, aluminum series, copper series, galvanized, color coated, coiled material, seamless pipe, welded pipe, square pipe, torque pipe, round steel, angle steel, channel steel, I-beam, hexagon Steel, square steel, flat steel, steel wire, welding rod, flange cutting parts and other stainless steel and high nickel alloy steel.

CLIENT FEEDBACK

The company's products are not only well received by domestic customers, but also exported to more than 50 countries such as the European Union, the United States, Australia, Southeast Asia, and the Middle East, and have established long-term and stable cooperative relations with them. Ruixing Steel Pipe welcomes new and old customers at home and abroad to visit and negotiate for win-win cooperation!

STORAGE VIDEO

APPLICATION FIELD

The products distributed by our company are guaranteed by the manufacturer, and have a complete pre-sale, in-sale and after-sales service system. Our company has a strong standing stock of thousands of tons, sufficient supply and complete specifications. It has formed an annual inventory turnover of more than 9,000 tons and more than 800 specifications.

mechanical

boiler plant

power plant

Chemical plant

Oil Pipelines

refrigeration equipment

Water pipes

Bearing

chemical plant

Natural Gas Pipeline

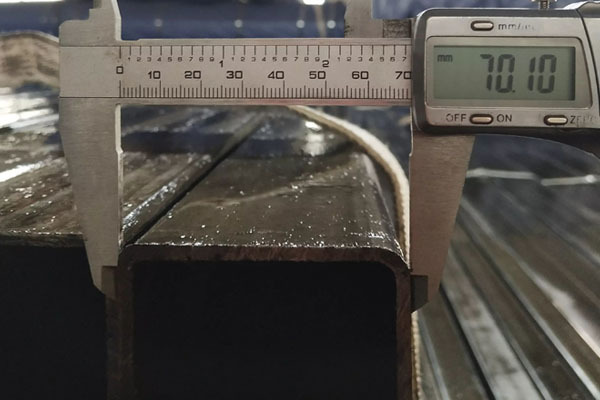

QUALITY INSPECTION

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your Inquiry and we will come back to as soon as possible.

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

PACKING AND SHIPPING

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your Inquiry and we will come back to as soon as possible.

Packing and shipping

Packing and shipping

Packing and shipping

Packing and shipping

Packing and shipping

RELATED PRODUCTS

GET A FREE QUOTE